BIOMASS PROCESSING

![]()

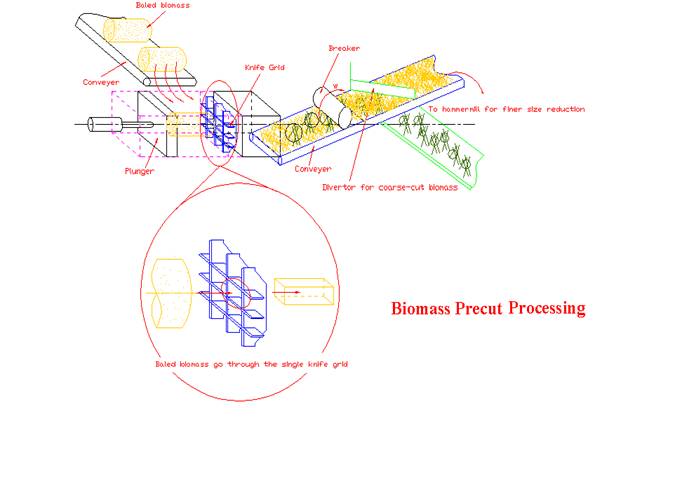

Linear Knife Grid The linear knife grid approach was identified to apply a high level of shear failure of biomass. A commercial application to process alfalfa/timothy hay is shown below (Fig. 1).

Figure 1. Knife grid concept to handle large bales, and large-scale commercial knife grid for biomass. A prototype knife grid was fabricated to evaluate size reduction energy, operating characterisitics, and particle size limits (Fig 2.). The grid with cut switchgrass (Fig 3), load–displacement curves (Fig 4), and energy versus refill runs (Fig 5), example mean separations for switchgrass are presented (Table 1). Conclusions for the linear knife grid studies were:

|

| |

||||||

| |

||||||

| |

|||||||||

| |

|||||||||

| |

|||||||||

| |

||||

| |

||||

| |

||||

| |

|